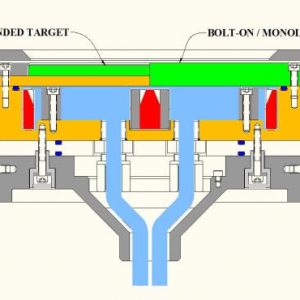

Rotary Magnetron

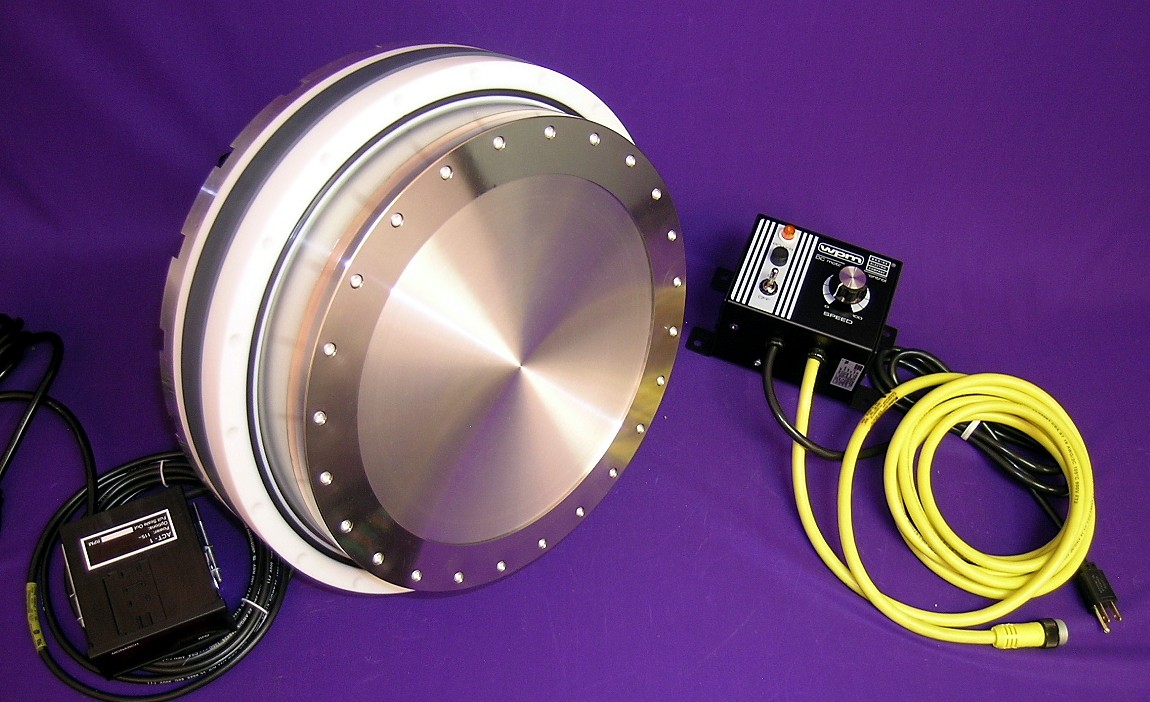

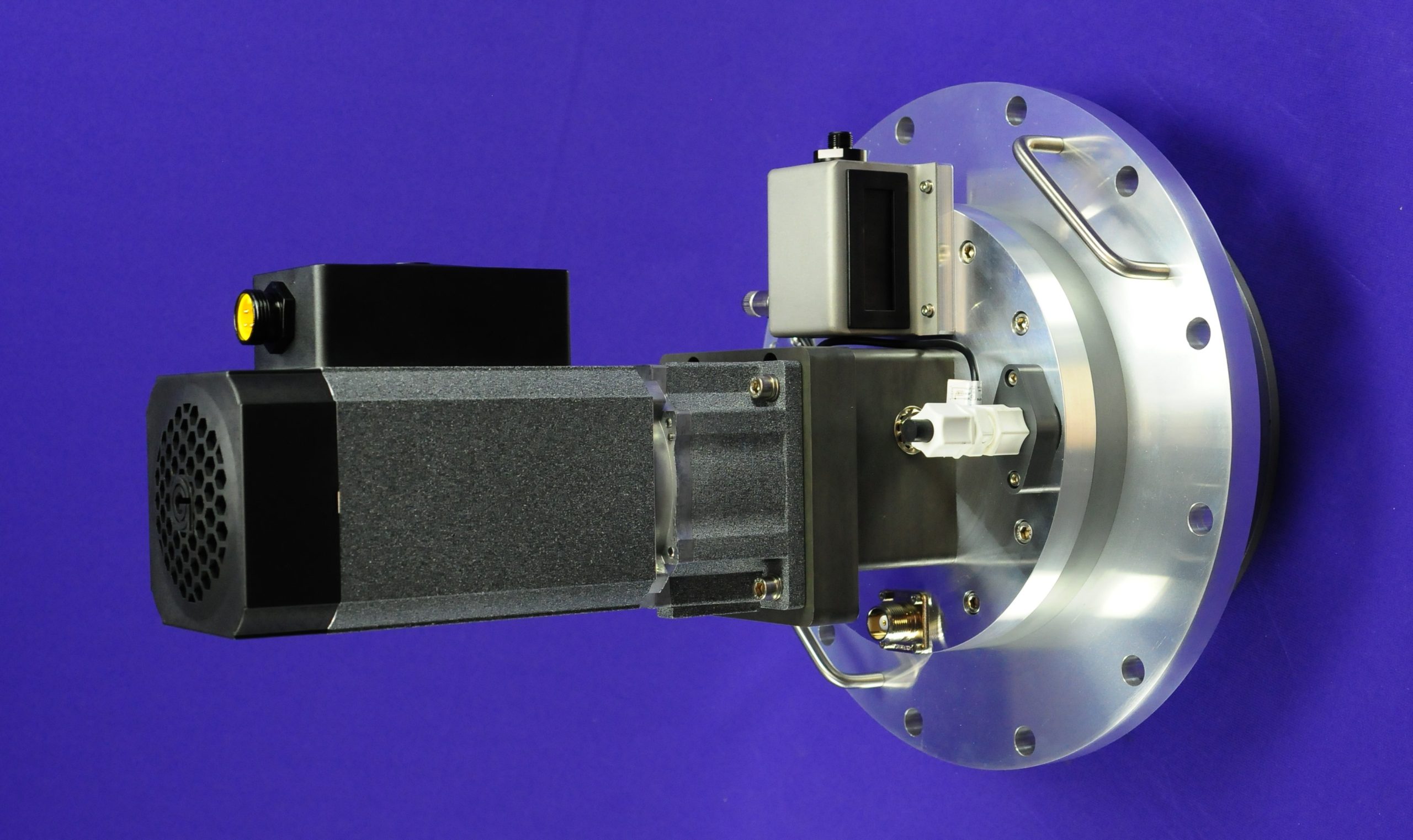

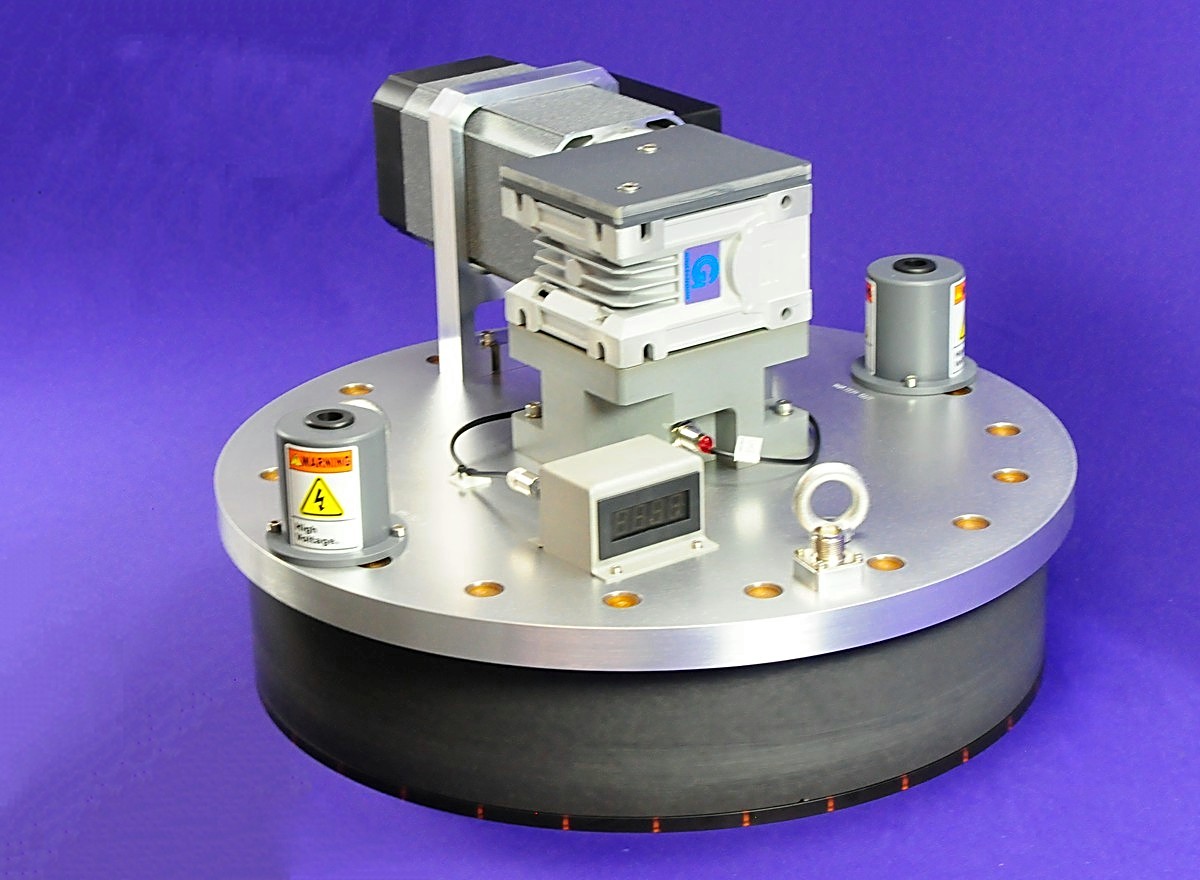

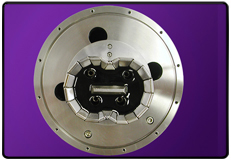

Rotary magnetrons are variants of a circular magnetron where the magnet set is mechanically rotated about a central axis. This embodiment, originally developed for semiconductor applications allows for the uniform coating of a stationary substrate with the smallest possible cathode diameter. Other applications of this technology include situations where material re-deposited on the target face generates defects in the growing film; in a rotary magnetron the entire target face is swept clean by a magnet set rotating between 20 and 600 RPM.

Description

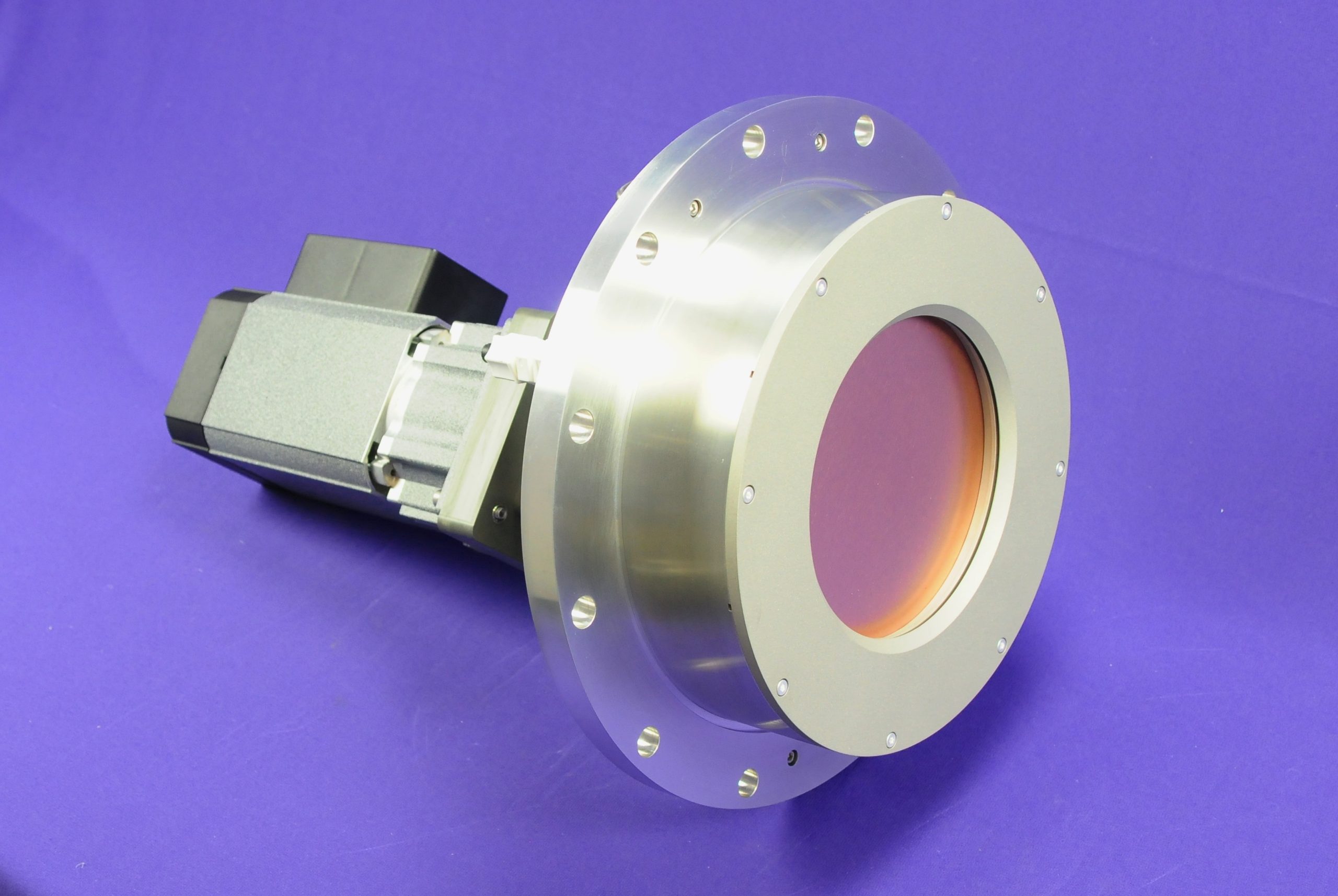

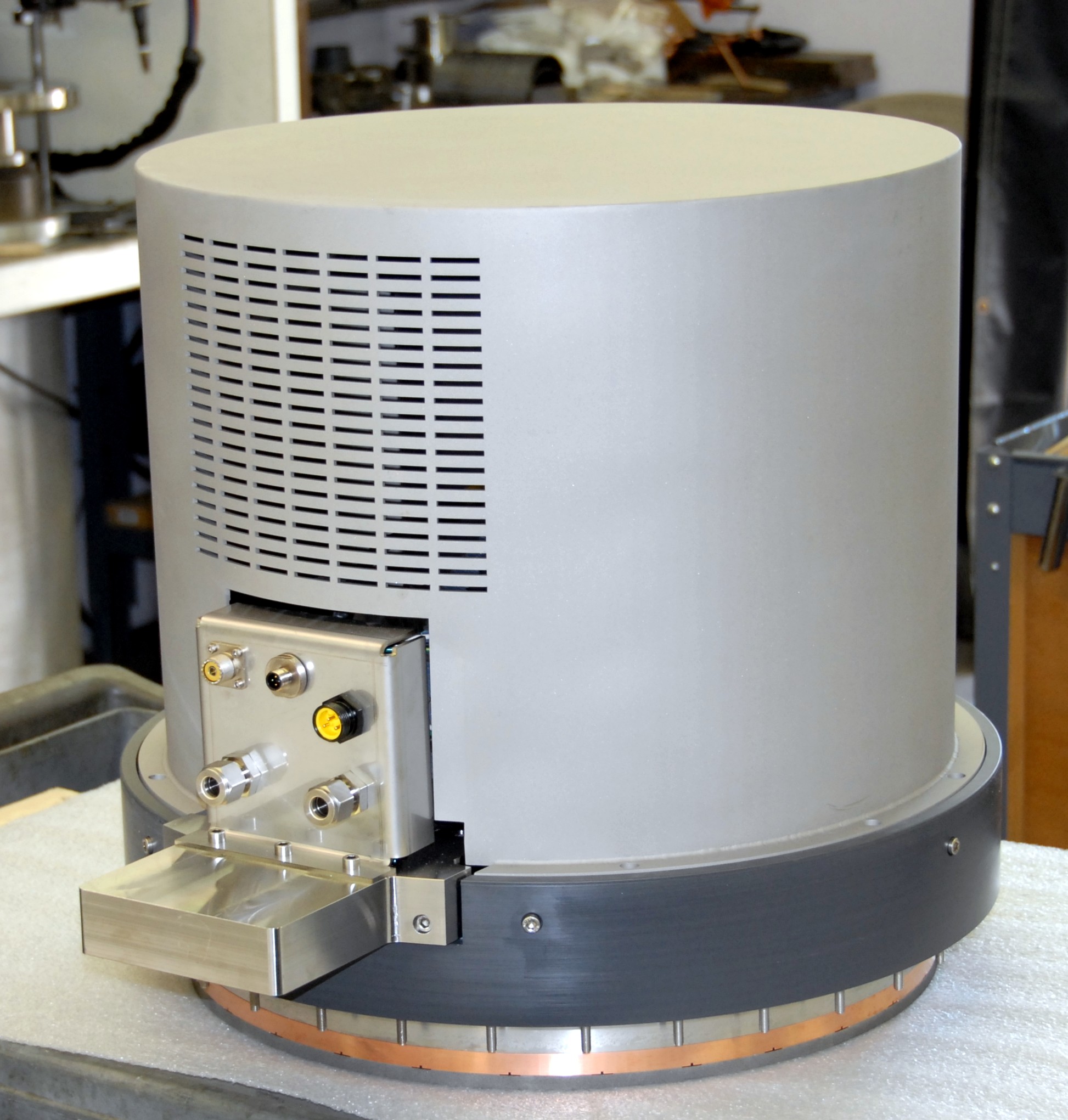

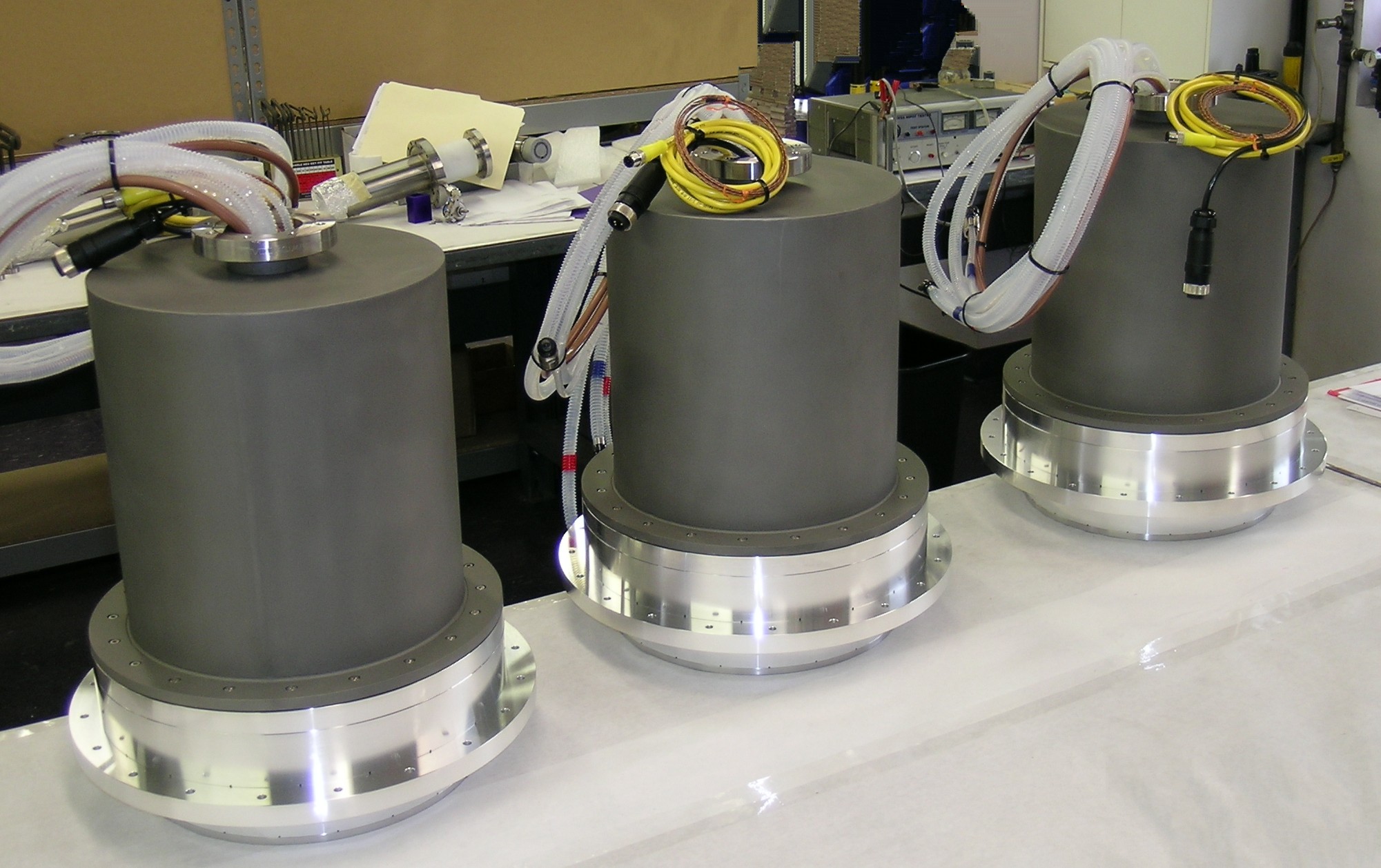

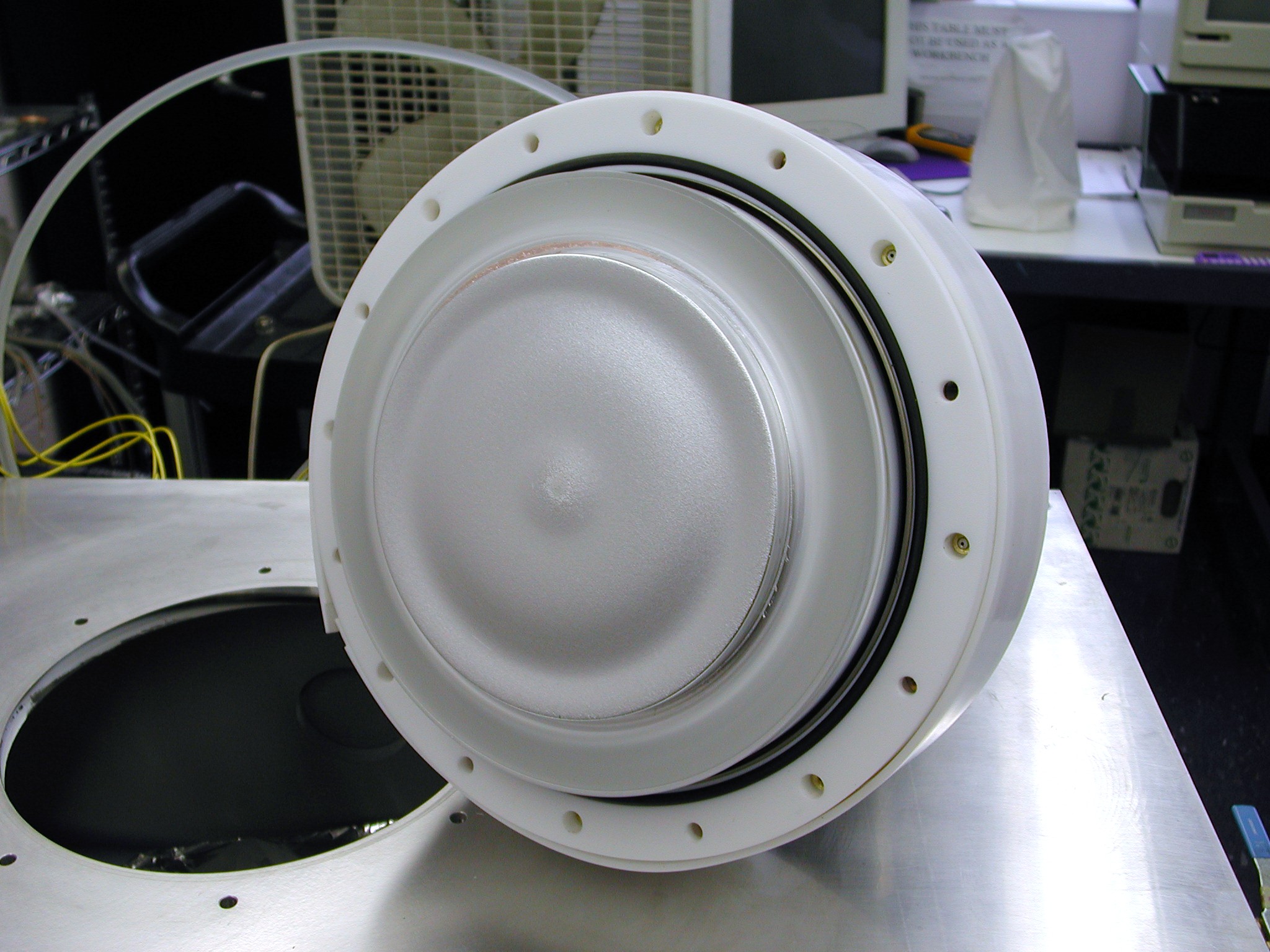

Angstrom Sciences offer a range of rotary magnetrons, from 4″ (100mm) up to 16″ (406mm) in diameter, and are designed with an adjustable magnet configuration allowing for process optimization and uniformity enhancement. Our magnetrons can be mounted in internal or external configurations.

Rotary Magnetron Benefits

A rotary magnetron offers excellent uniformity without movement of the substrate. This combined with full face erosion provides extremely low defects caused by particulate contamination. These magnetrons can also be integrated into machines with a limited amount of space, providing more flexibility in your application.

For more information about Rotary Magnetrons or how Angstrom Sciences can help your business call 412-469-8466 or contact us online .

You must be logged in to post a review.

Reviews

There are no reviews yet.