Sputtering Power Supplies

Home » Sputtering Power Supplies

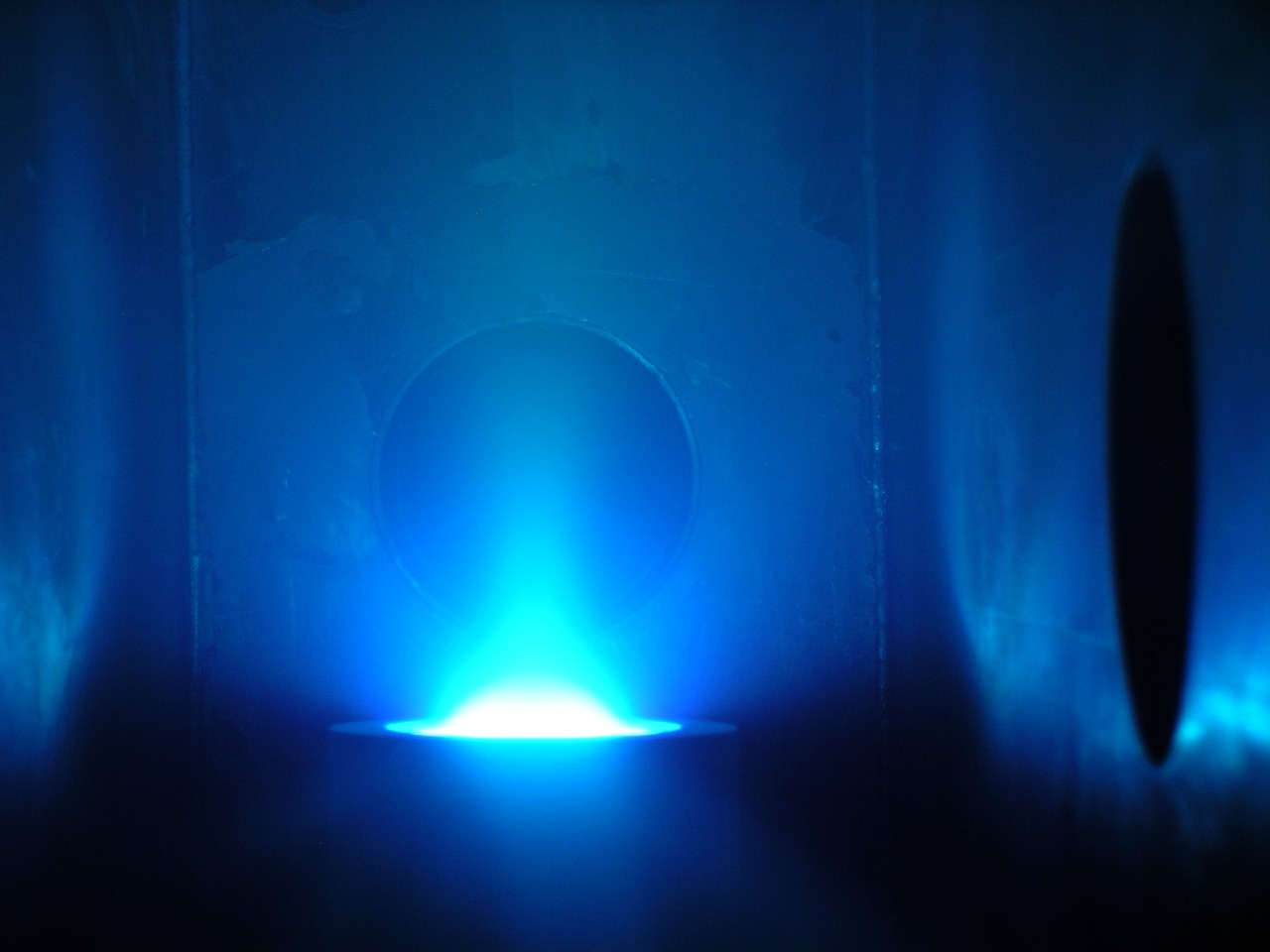

Sputtering Power Supplies

There are several types of power supplies used in magnetron sputtering, these include DC, RF, Pulsed DC, MF AC, and HIPIMS. Below is a brief description outlining the differences between these power types.

DC Direct Current Sputtering Power

DC Power is generally used with electrically conductive target materials. It is easy to control and a low cost option.

RF Radio Frequency Sputtering Power

RF Power can be used with all materials, but generally finds most use in depositing films from dielectric target materials. The deposition rate (driven by the relative duty cycle) when compared to DC is generally quite low and the electron flux (due to the mobility difference of electrons and ions in a plasma) on the substrate is much higher and may cause significant heating. Due to the major cost considerations of RF power supplies, RF deposition is generally limited to smaller substrate sizes.

Pulsed DC Sputtering Power

Pulsed DC (variable frequency) has found broad application in reactive sputtering applications where a positive voltage spike, induced at some frequency on the power waveform can be used to clean the target face and eliminate the buildup of a thick dielectric layer which can be prone to arcing. Frequency ranges from 40 to 200 KHz are typically used. This approach is commonly referred to as uni-polar pulsed sputtering. Another option known as bi-polar pulsed sputtering uses two pulses ,180 degrees out of phase, that are applied to two adjacent magnetrons in which each magnetron alternates as both a cathode and anode, mitigating the effects of dielectric build-up and greatly reducing the disappearing anode effect. This technique has also found wide industrial use.

MF Mid Frequency AC Sputtering Power

MF Sputtering is typically used to deposit non-conductive materials. Two cathodes in a dual configuration are used and the AC current is switched between each cathode allowing the target surface to be cleaned with each reverse of the cycle. This reduces arcing by charge build up and eliminates the need for anode cleaning which provides long term process stability. MF sputtering is widely used in many in line production systems today.

HIPIMS

High Power Impulse Magnetron Sputtering is a emerging process which uses a high current pulse to greatly increase the ionization of the sputtering material. These ionized atoms have much higher energies than sputtered atoms in conventional magnetron sputtering and have been found to yield very dense and stable films.

For more information regarding Sputtering Power Supplies or to discuss your project, call 412-469-8466 or contact us online.

If you would like a quotation, please fill out this Power Supply Questionnaire.