ONYX-Flux Control

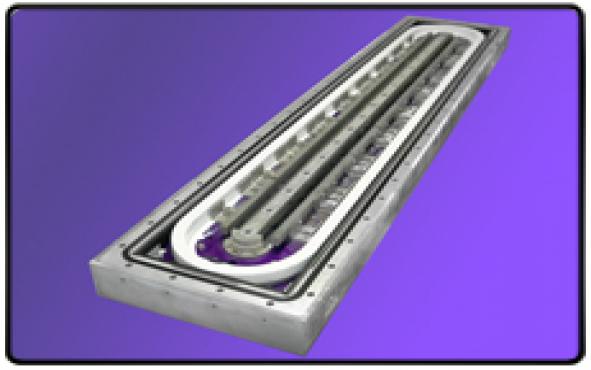

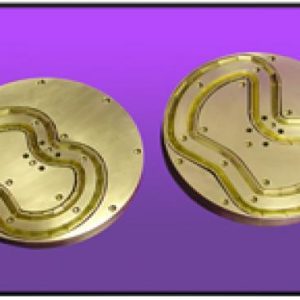

Angstrom Sciences is internationally known for the cutting edge technology we bring to magnetron sputtering applications. We have now developed a method to control the plasma across the surface of the target. The ONYX-Φlux Control, (Flux Control) developed for both planar and circular magnetrons, allows the user to maximize uniformity or target utilization.

Description

Control Uniformity

Programmable dwell time of the magnetic field at specific points on the target surface. Provides precise control of electrical and magnetic field crossing point to focus the erosion profile and tune uniformity.

Control Material Utilization

Sweeps the plasma across the target surface at a constant rate. Up to 65% Target Utilization can be achieved on flat planar targets with thicknesses up to 1.4″ (35mm) allowing for extremely long run times.

User Friendly Software

- Intuitive user interface

- Three user modes – Run, Edit, Manual

- Touch screen technology

- Input position of the plasma and dwell time

Total Commitment

Angstrom Sciences is dedicated to helping our customers develop the most productive and cost-effective thin film applications by providing the world’s most advanced magnetrons, high quality deposition materials, and comprehensive technical support. We stand by ready to ensure your satisfaction. That is why we back all of our magnetrons with a 2-year warranty, the longest in the industry.

Click Here, if you want to Configure your Magnetron.

For more information about our ONYX-Φlux Control, call +1-412-469-8466 or contact us online.

You must be logged in to post a review.

Reviews

There are no reviews yet.