The Angstrom Advantage

Home » Sputtering Magnetron Advantage

The Angstrom Advantage

Better Technology

Every sputtering application has process parameters, system requirements, and performance goals. The patented technology within the Angstrom Advantage™ optimizes our cathodes to meet your specifications, whether you require high uniformity and target utilization, high rate and throughput, or a perfect balance between the two.

Optimized Performance

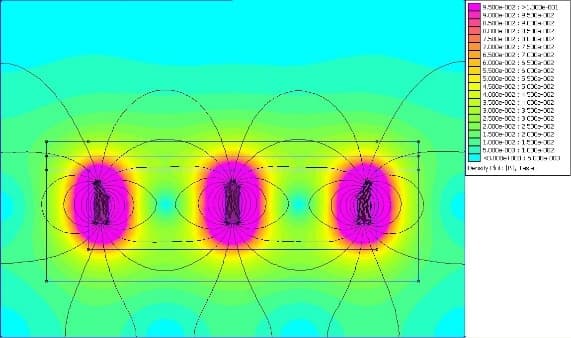

Because the shape of the magnetic field affects critical performance factors, we use Finite Element Analysis (FEA) Computer Modeling to custom engineer the magnet array that matches your specific application. We then profile our magnets into contours that create a wider, flatter magnetic field and optimize your performance.

More Efficient Cooling

Turbulent water flow is designed into every Angstrom Sciences cathode to provide more efficient cooling across the cathode body. This patented technical advancement minimizes the “hot spots” that cause grain boundary dissociation and cracking within thermally sensitive materials.

Faster, Easier Target Change

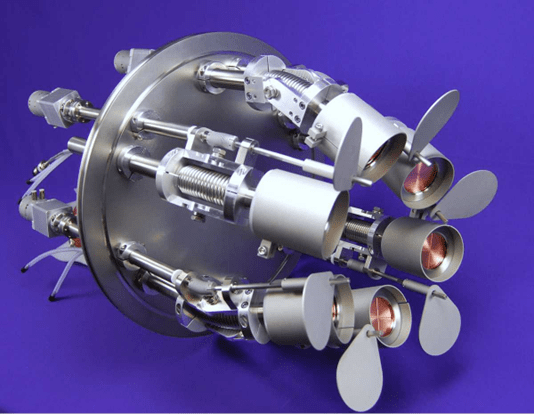

The threaded target clamping system in our circular cathode design adjusts to variable target thicknesses without the use of extra tools and devices. In addition, it provides the fastest, easiest method available for target changes, minimizing your system downtime.

Stronger Design

We machine each magnetron from solid 304 Stainless Steel 6061 Aluminum, and OFHC Copper. This ensures magnetic and electrical integrity for long-term, reliable operation.

Comprehensive Service

Every cathode from Angstrom Sciences is guaranteed against defects in workmanship and materials for two full years—the longest warranty in the industry. And we provide technical support for the lifetime of your cathode.

More Capabilities

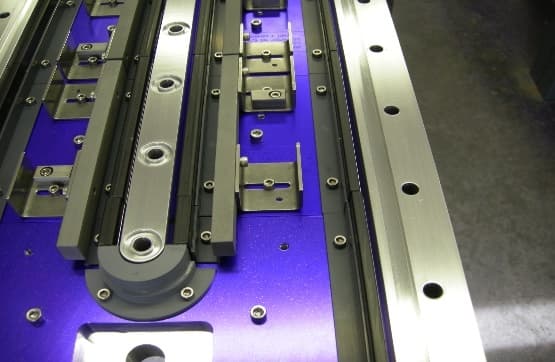

Angstrom Sciences designs, engineers, and manufactures its magnetrons in-house. From FEA and 3D CAD modeling to state-of-the-art CNC Machining and Assembly & Testing, we guarantee the highest quality and control.

More Options

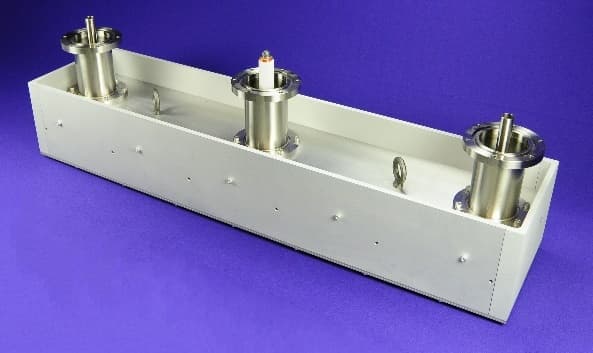

Our business is focused on providing a comprehensive line of the most advanced sputter sources in the industry. With over 35 years of experience in design, engineering, testing, and manufacturing we provide a complete range of circular, planar, and cylindrical cathodes in target sizes ranging from 1”/25 mm diameter to over 157”/4 meters in length.

Mission

Our purpose is to help our customers develop the most productive and cost-effective thin film applications on the market by providing the world’s most advanced magnetrons, high quality plasma vapor deposition materials, and comprehensive technical support.

For more information about the Angstrom Advantage or to discuss your project, call 412-469-8466 or contact us online.

The Angstrom Advantage

1.5"/ 38mm Target Width

Magnetron sputtering technology has been utilized in production applications for several decades. The basic technology used to control process plasma within the deposition process is well established within the field; however the capabilities available to optimize process efficiencies, such as thin film uniformity, target utilization, and deposition rate, are continuously evolving.

Angstrom Sciences is focused upon the development of magnetron sputtering cathodes that optimize sputter process performance. The Angstrom Advantage™ is the collective set of technical and structural advancements Angstrom Sciences has designed into its magnetrons in order to provide its clients with the most control over their thin film deposition process.

Angstrom Sciences strives for all our customers to have complete satisfaction with our products. We offer a 2-year warranty against defects in workmanship and materials on all our magnetrons, which is the longest in the industry. We offer unlimited post-sale support to all our customers. With over 25 years of experience in the industry, we have a wealth of knowledge not only on magnetrons, but the processes they are used in. We feel it is important to share this knowledge with our customers, so that they are successful. We feel that our continued success is driven by that of our customers.

We use only the highest qualtity materials, design and manufacturing techniques in order to provide the best possible product. Our in-house manufacturing capabilities along with a full-scale R&D and test lab give us the ability to fully control design development, manufacturing, and pre-shipment testing for on-time deliveries.

For more information about the Angstrom Advantage or to discuss your project, call 412-469-8466 or contact us online.