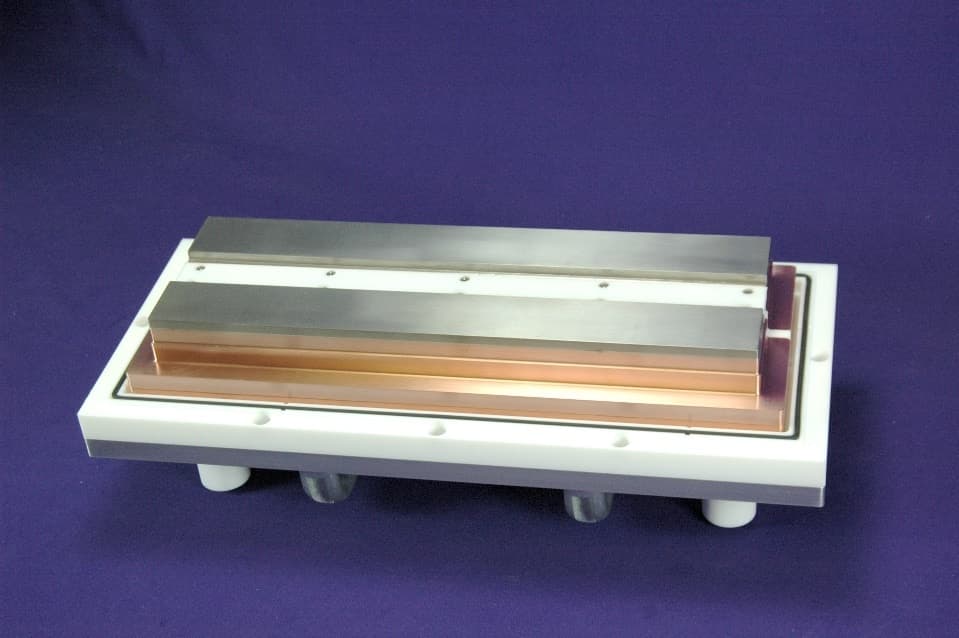

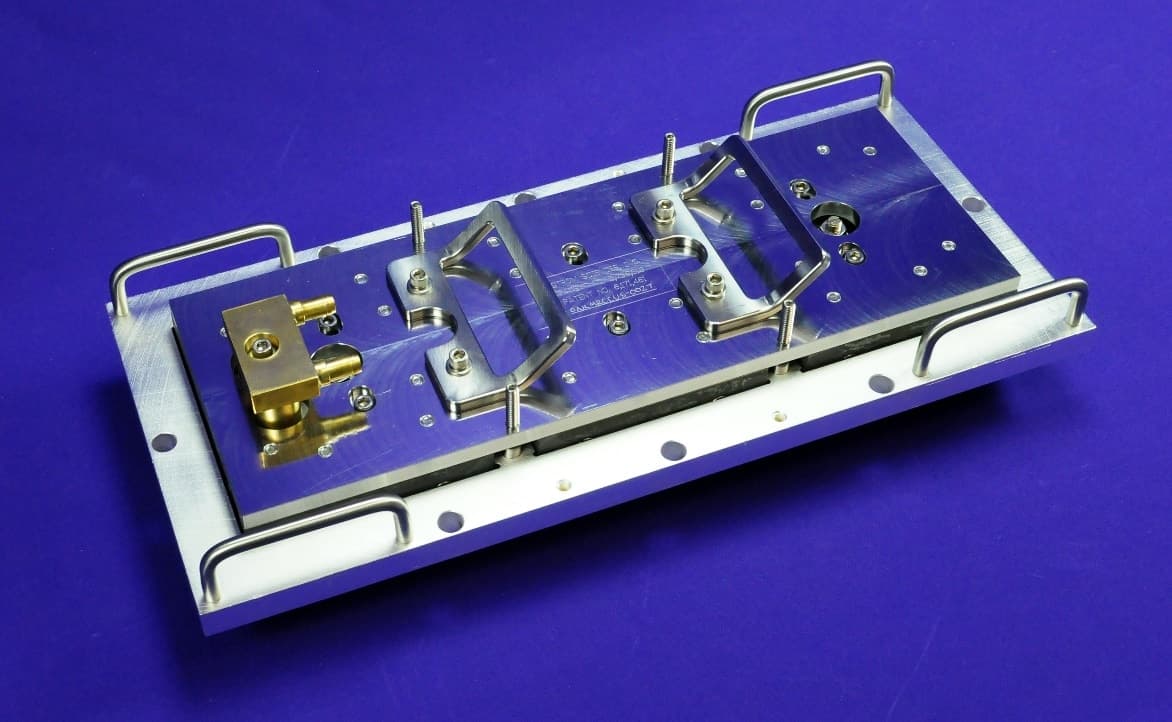

MRC Magnet Retrofit

Angstrom Sciences is internationally known for the cutting-edge technology we bring to magnetron sputtering applications. Now, we’ve developed a method for retrofitting your existing MRC style magnetrons with our patented, profiled magnet design – bringing the Angstrom Advantage™ to your process.

Economical Solution

An MRC magnet retrofit provides the performance advantages of our profiled magnet technology at approximately one-third of the cost to replace your entire existing MRC assembly.

Description

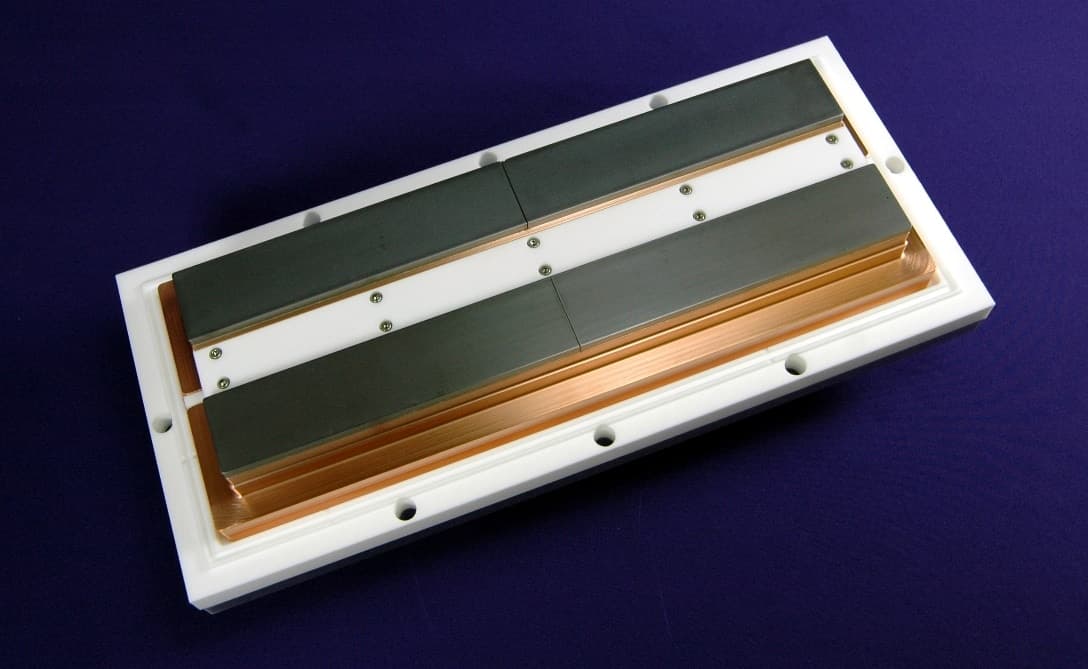

Intelligent Design

- Fully encapsulated magnets

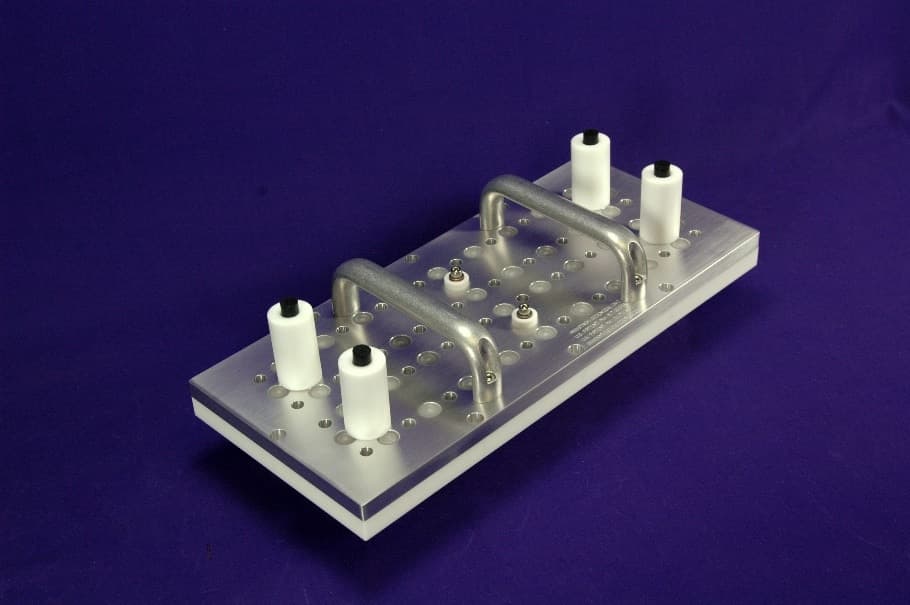

- Turbulent water flow

- Increased thermal efficiency

- Fast and easy drop-in design

- Seamless integration

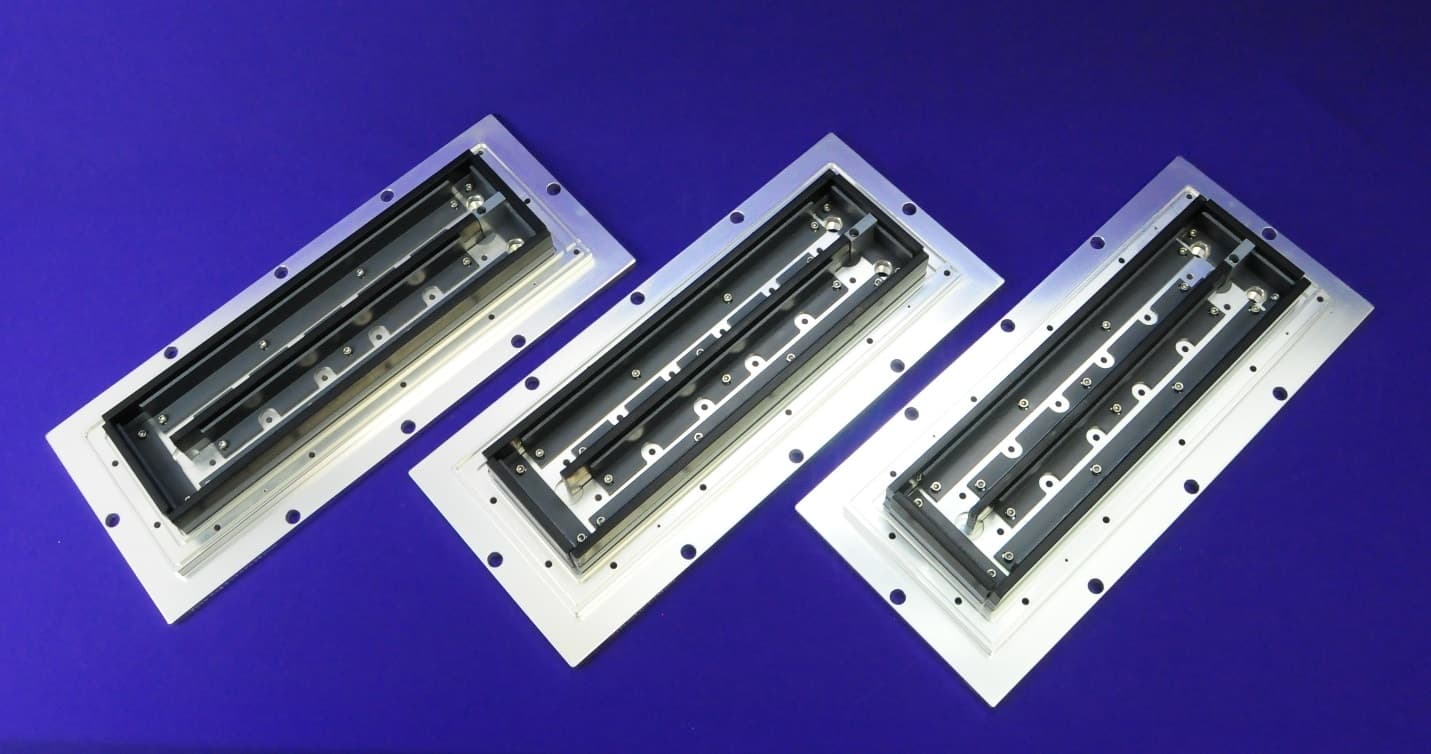

Magnetic Options with Proven Results

- High Utilization Array – 35% and greater target utilization

- High Uniformity Array – Increased uniformity zone with minimal sacrifice to utilization

- High Mag Array – Optimized to sputter up to 0.500″ thick Nickel

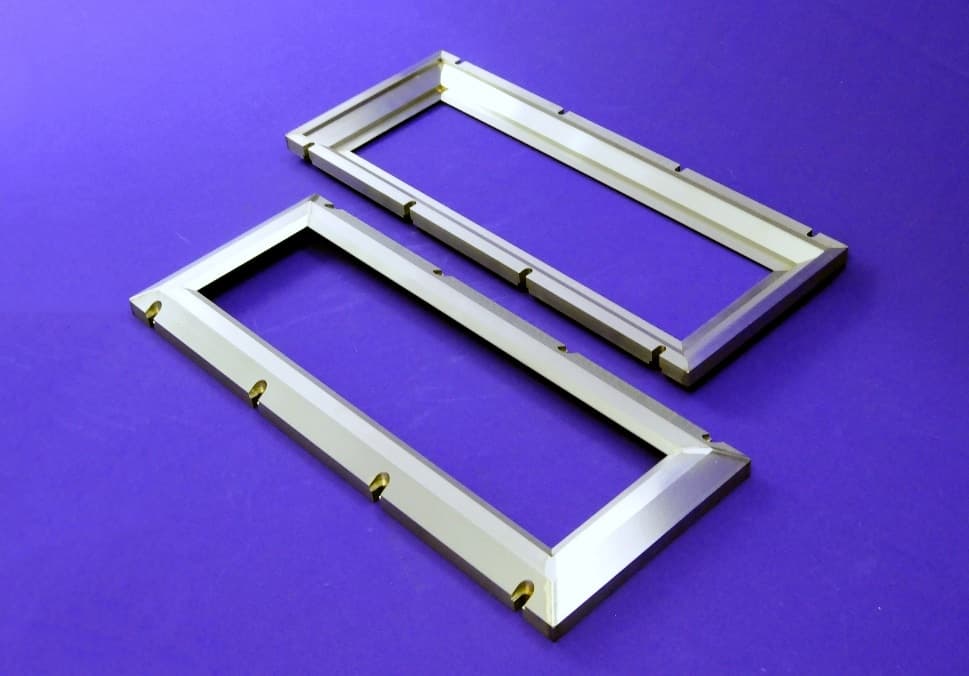

Other Options

- MRC Inset style upgrades

- Clamped Target Conversions

- Custom target widths 1.0”/ 1.5”/ 2.0”/ 3.0”

- Dual targets in an existing single space.

- Complete sparts for any cathode.

Total Commitment

Angstrom Sciences is dedicated to helping our customers develop the most productive and cost-effective thin film applications by providing the world’s most advanced magnetrons, high quality deposition materials, and comprehensive technical support. And we stand ready to ensure your satisfaction. That’s why we back all of our magnetrons with a 2-year warranty, the longest in the industry.

For more information about MRC Magnet Retrofits call 412-469-8466

You must be logged in to post a review.

Reviews

There are no reviews yet.