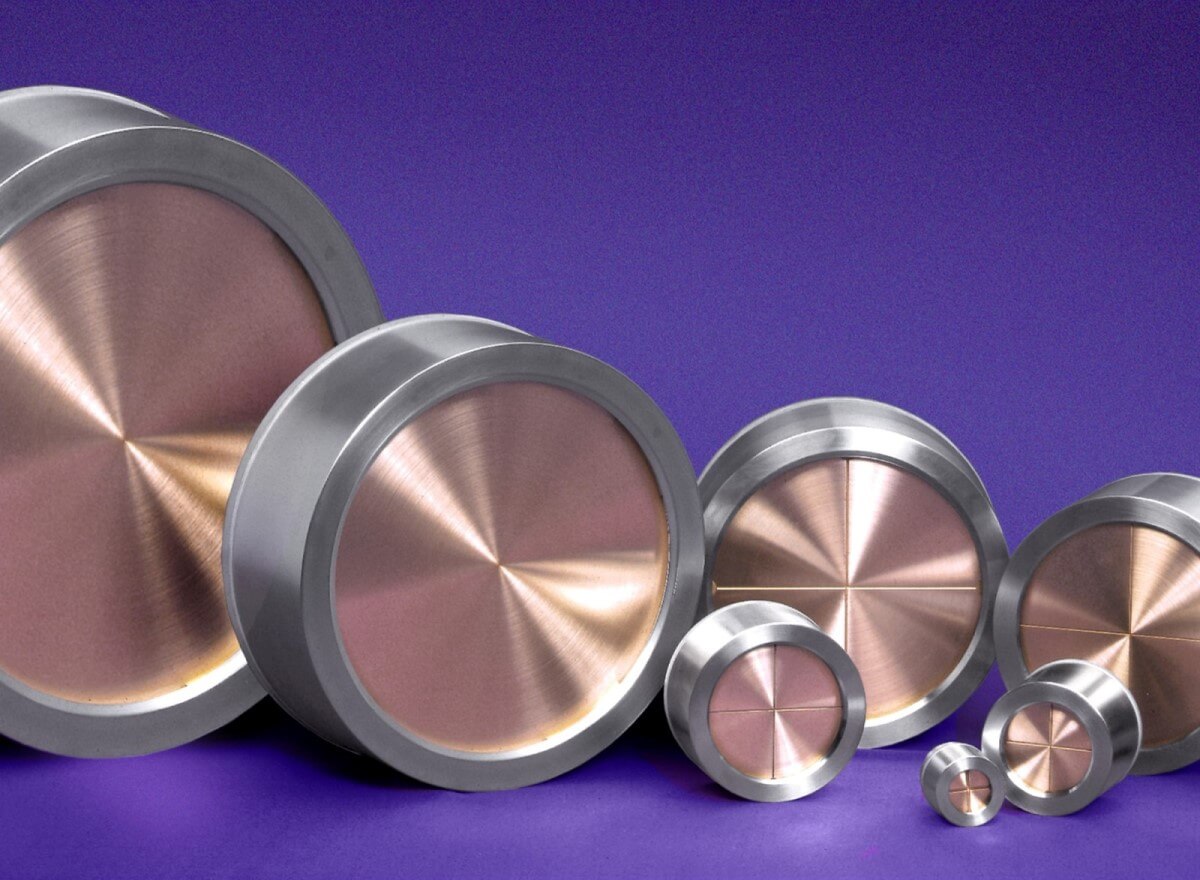

Circular Magnetron

Angstrom Sciences’ circular magnetrons have become recognized as the standard of the sputtering industry because of the Angstrom Advantage™ and a host of other design features that deliver almost unlimited possibilities in configuration and process performance.

Description

Versatile, Compact Design

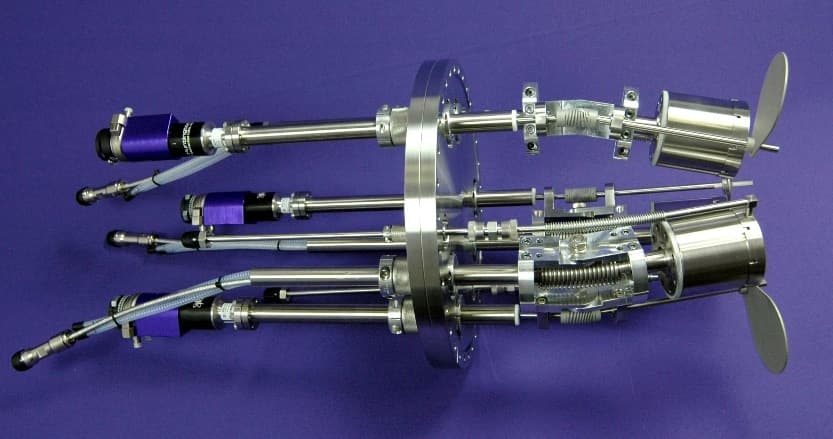

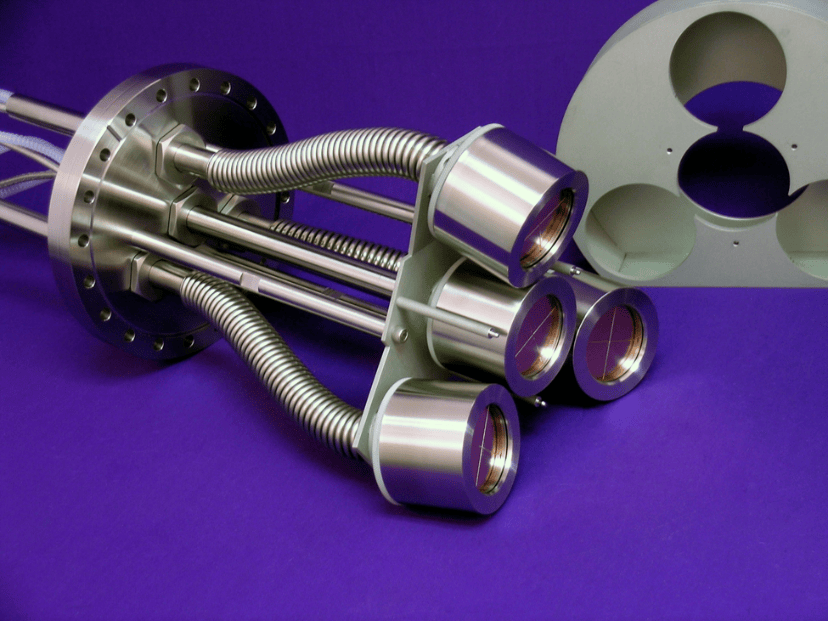

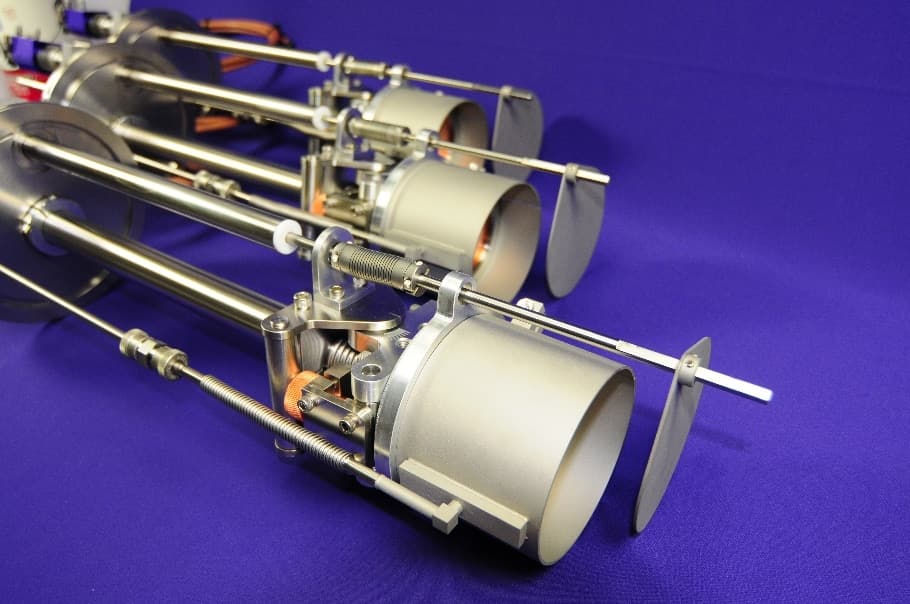

Their compact design makes our circular magnetrons ideal for any new or retrofit application, including the most complex cluster assemblies for the smallest vacuum chambers.

Total Power Compatibility

Low-impedance heads provide RF, DC, mid-frequency DC, pulsed DC, HiPIMS, and microwave power compatibility.

Standard Fittings

We use ISO NW standard fittings, as well as Conflat® metal seal flanges. All utilities are maintained at atmosphere and are accessed through standard O-ring compression fittings for easy installation in any vacuum system.

Full Range of Sizes

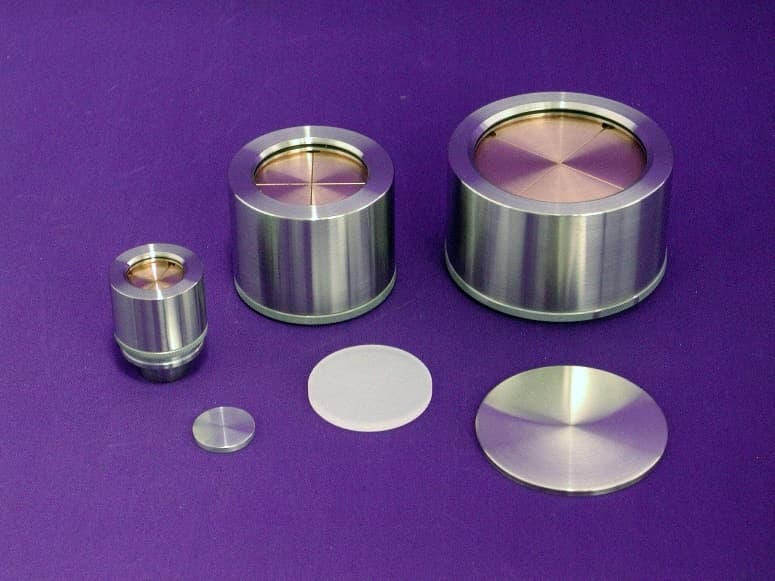

Circular magnetron sources are available from 1″ (25mm) through 16″ (406mm) and larger target diameters in either standard or custom configurations.

Quick, Easy Target Change

Our patented threaded target clamp and anode shield on our small circular cathodes allow you to change targets without the use of ancillary tools. Their built-in adjustability also lets you fit targets of varying thickness without using any spacing devices.

Lower, Pressure, High Power

ONYX® magnetrons can operate at extremely low pressure (down to the 10-4 Torr range), and our direct cooled designs can deliver power densities up to 250 watts/in2 (30 watts/cm2) continuous operation.

High Rates and Performance

With higher power densities, you can coat a substrate faster. So, Angstrom Sciences maximizes both your coating zone and your target utilization (usually in the 40% range) without a trade-off in rate.

Greater Uniformity

Thanks to our patented profiled magnets, our magnetrons also deliver much greater uniformity of deposition – routinely in the ± 1-3% range.

Low Contamination

Because the field is spread across the entire target face, defects from particulate contamination and re-deposition are minimized.

Total Commitment

All Angstrom Sciences’ magnetrons are guaranteed against defects in workmanship and materials for two full years. Magnetrons are our core business, and we stand ready to ensure your satisfaction.

Click Here, if you want to Configure your Magnetron.

For more information about Circular Magnetrons, please call +1-412-469-8466 or contact us online.

You must be logged in to post a review.

Reviews

There are no reviews yet.