Sputtering Technology

Home » Sputtering Technology

Sputtering Technology

Sputtering is a Physical Vapor Deposition vacuum process used to deposit very thin films onto a substrate for a wide variety of commercial and scientific purposes. Sputtering occurs when an ionized gas molecule is used to displace atoms of a specific material. These atoms then bond at the atomic level to a substrate and create a thin film. Several types of sputtering processes exist, including: ion beam, diode, and magnetron sputtering. Angstrom Sciences specializes in Magnetron Sputtering Technology.

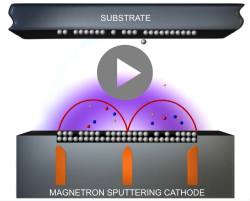

In a magnetron sputtering application, the high voltage is delivered across a low pressure gas (usually argon) in order to create high-energy plasma. This plasma emits a colorful halo of light often referred to as a “glow discharge” and consists of electrons (yellow) and gas ions (red).

These energized plasma ions strike a target composed of the desired coating material. The force causes atoms to eject from the target material and bond with those of the substrate.

Because sputtering takes place in a high-energy environment, it creates a virtually unbreakable bond between the film and its substrate at the atomic level, creating one of the thinnest, most uniform, and most cost-effective films possible.

So, given the right tools, researchers and engineers in a variety of industries can use this technique to create a whole new generation of smaller, lighter, more durable products.

For more information on Sputtering Technology, call us at 412-469-8466 or contact us online.